Introduction

In the competitive and ever-evolving ERP systems for manufacturing industry, relying solely on efficient production processes is no longer enough. Manufacturers need intelligent, integrated digital solutions to streamline operations and stay agile in changing markets. This is where production ERP software revolutionizes operations—empowering manufacturers to manage workflows, data, and resources with greater visibility and control.

What is Production ERP Software?

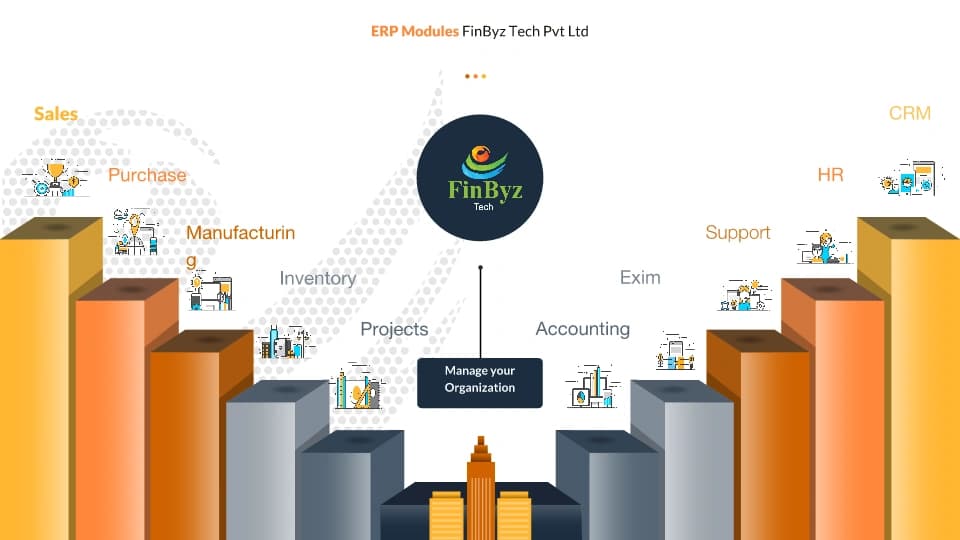

ERP software for manufacturing is a comprehensive solution designed to integrate and optimize every stage of the manufacturing process. From procurement and planning to inventory and quality control, production manufacturing software unifies all essential functions into a single system. The result is improved collaboration, reduced delays, and full visibility across the entire production lifecycle.

Key Features and Benefits

End-to-End Insight

Production ERP software offers real-time, end-to-end insight into operations from raw material procurement to final product delivery. This level of visibility allows manufacturers to monitor inventory levels, track production progress, and quickly resolve operational issues, ensuring efficiency across the entire production manufacturing software ecosystem.

Effective Resource Management

With ERP systems for manufacturing, companies can manage resources such as labor, machinery, and materials more efficiently. These systems include planning tools that reduce downtime, eliminate resource waste, and enhance production flows—leading to optimized performance and cost savings.

Simplified Production Scheduling

Production manufacturing software enables manufacturers to create dynamic, data-driven schedules that align with resource availability and demand. This proactive approach reduces production delays, minimizes overstocking, and supports lean manufacturing practices.

Quality Control and Compliance

Production ERP software integrates quality checks and regulatory compliance directly into the production workflow. This ensures that products consistently meet quality standards while helping manufacturers maintain certification and regulatory requirements without added complexity.

Data-Driven Decision Making

Production ERP software enables manufacturers to harness data from all departments into one centralized system. These insights, backed by real-time analytics, help businesses evaluate key metrics, improve forecasting, and make strategic decisions that elevate the performance of their production manufacturing software.

Enhanced Co-operation

ERP systems for manufacturing promote transparent communication and smooth coordination across departments like production, procurement, and quality control. By breaking down data silos, production ERP software fosters collaboration that enhances operational synergy and output quality.

Scalability and Flexibility

As companies evolve, ERP systems for manufacturing offer scalable solutions that adapt to growing demands. Whether expanding product offerings or navigating compliance updates, production manufacturing software ensures continuity, flexibility, and seamless integration with business objectives.

Choosing Suitable Production ERP Software

When selecting the right production ERP software, consider factors such as the provider's industry experience, scalability of the solution, integration capabilities, and the ability to support specialized manufacturing workflows. A well-evaluated choice ensures that your production manufacturing software enhances productivity and aligns with long-term goals.

Conclusion

In conclusion, ERP systems for manufacturing have become a strategic necessity in today’s dynamic industrial landscape. With the ability to automate processes, optimize production flow, and support data-backed planning, production ERP software empowers manufacturers to remain agile, competitive, and growth-ready.

.webp&w=1080&q=75)