ERPNext for Manufacturing

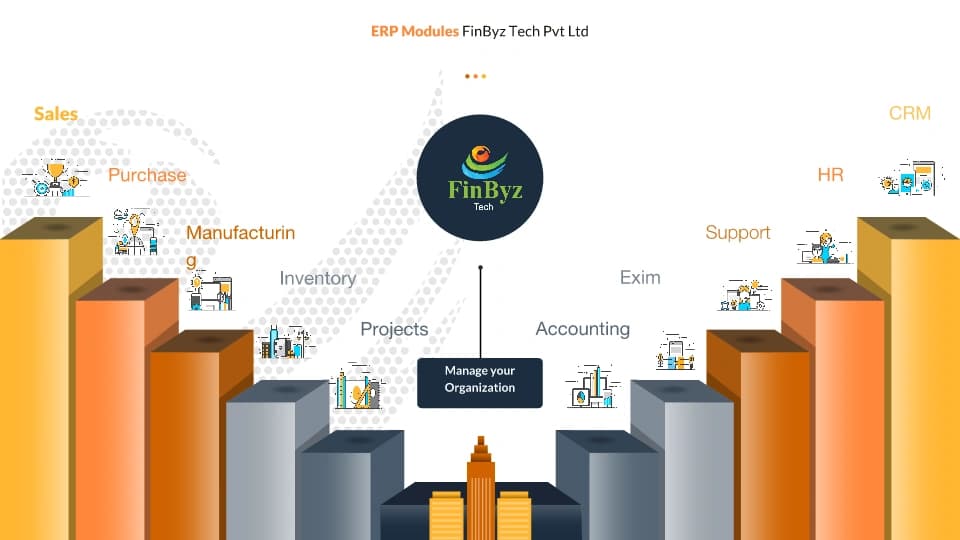

FinByz Tech’s ERPNext manufacturing ERP software streamlines production and inventory management, reducing costs and improving efficiency.

ERP software for Manufacturing industry

"The surest foundation of a Manufacturing concern is quality. After that, and a long way after, comes cost – Andrew Carnegie"

In today's competitive environment, manufacturing companies need more than just machines and manpower—they need smart systems to run efficiently. ERP software tailored for the manufacturing industry brings all business functions like production, inventory, sales, finance, and HR into a single, centralized platform. This integrated approach enables real-time visibility, better decision-making, and significant cost savings.

Modern ERP systems like ERPNext are designed to handle the unique challenges manufacturers face—from complex supply chains to rapid changes in customer demand. Whether you're producing on a small scale or running a large facility, manufacturing ERP software helps you stay in control, reduce waste, and deliver high-quality products on time.

Why ERP is Crucial for Modern Manufacturing ?

"Continuous learning and smart process automation are the minimum requirements for success in modern manufacturing - Brian Tracy"

Manufacturing processes involve many interconnected activities: procurement, production planning, shop floor control, inventory tracking, and delivery. Without an ERP system, these processes often operate in silos, leading to delays, miscommunication, and inefficiencies. A robust manufacturing ERP system bridges these gaps by:

- Unifying Departments: Connects production, finance, inventory, sales, and HR into one system.

- Real-Time Visibility: Tracks operations live from raw materials to finished goods.

- Automated Workflows: Reduces manual effort by automating tasks like material requests, production scheduling, and billing.

- Improved Decision-Making: Managers access up-to-date information instantly, helping them make informed decisions.

An effective manufacturing ERP is a game-changer. It optimizes every aspect of production—from inventory management and scheduling to quality control and supply chain logistics. With real-time insights and automation, ERP helps manufacturers make informed decisions, reduce production costs, minimize waste, and improve overall productivity.

Types of ERP in Manufacturing

Manufacturing spans many sectors (engineering, chemicals, retail, etc.), so ERP solutions are classified accordingly. Below are common types of ERP systems in manufacturing:

ERP for Discrete Manufacturing

Discrete manufacturers assemble components into finished products (e.g., electronics or automotive). An ERP for discrete manufacturing manages demand forecasting, serialized production, supplier information, and order tracking to ensure smooth assembly operations.

ERP for Process Manufacturing

Process manufacturers combine formulas or raw materials to produce goods (e.g., chemicals, food & beverage). ERP for process manufacturing handles complex recipes and formulas, quality control, waste tracking, and product life cycles to maintain consistent output.

ERP for Mixed Manufacturing

Mixed manufacturing companies perform both discrete and process production. An ERP for mixed manufacturing supports both assembly and formula-based processes in one system, giving flexibility to businesses dealing with varied production models.

Benefits of ERP for Manufacturing

"Continuous improvement is better than delayed perfection – Mark Twain"

Implementation of ERP Software is the answer to many problems related to management in the manufacturing industry. The industry in today’s business environment is very dynamic and innovating rapidly. For being at the same pace as the changing market, latest technology is a must as ERP Software has various benefits, some of them are as follows:

Cost Reduction

ERP systems automate repetitive tasks, reduce paperwork, and optimize resource utilization. By minimizing manual errors and streamlining procurement, production, and inventory processes, companies save both time and money.

Real-Time Visibility

Get up-to-date information on stock levels, production status, pending orders, and delivery timelines. Real-time dashboards help supervisors monitor the shop floor, identify bottlenecks, and respond quickly.

Flexibility and Competitive Edge

ERP systems are highly customizable. Whether you're producing seasonal goods, managing job orders, or dealing with varying customer specs, ERP adapts to your workflow giving your business a competitive edge.

Key Benefits of ERP in Manufacturing

"Time is needed to convert all ideas and added values into tangible products that benefit the world. - Sunday Adelaja"

The key benefits of implementing an ERP system in the manufacturing industry include:

Reduces operating costs

Standardizes business processes

Improves supply chain management

Aligns operations with strategic business goals

Maintains product quality

Enhances overall efficiency

Conclusion

ERP for Manufacturing provides end-to-end solutions to every kind of industry by increasing the efficiency of the business and helping in its growth in the market. Given the complexity of operations, ERP plays an important role in the manufacturing industry by keeping track of orders and delivery dates, production planning and scheduling, optimizing delivery time, and management of waste and other activities related to manufacturing. Doing everything manually makes it very difficult in the growing dynamic environment and brings a vast possibility of errors and failures. It centralizes and integrates all the operations and departments in a standardized way. It also helps in facing major challenges faced by manufacturers. Management and security of data become advantageous in the long run to achieve the objectives of organizations and increase profits and productivity.

"Almost all quality improvements come via simplification of design, manufacturing, layout, processes, and procedures - Tom Peters"

.webp&w=1080&q=75)