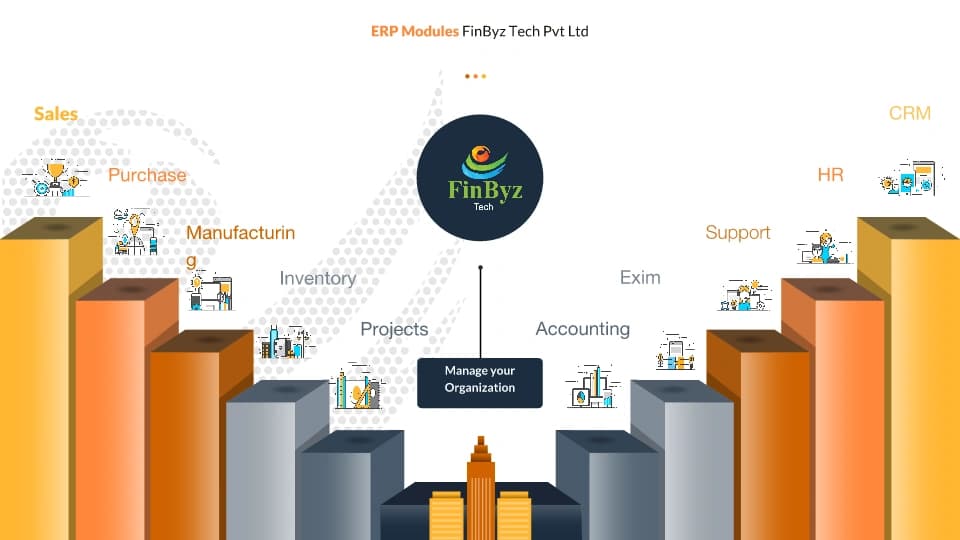

Manufacturing

Discover how Finbyz's ERP Manufacturing solutions streamline production processes, enhance efficiency, and support growth. Explore the best ERP systems tailored for manufacturing industries.

The production process lies at the core of every manufacturing operation. For businesses to remain profitable and competitive, they must efficiently manage raw materials, resources, and operational costs. This is where ERP Manufacturing plays a vital role offering integrated tools that optimize each step of the process.

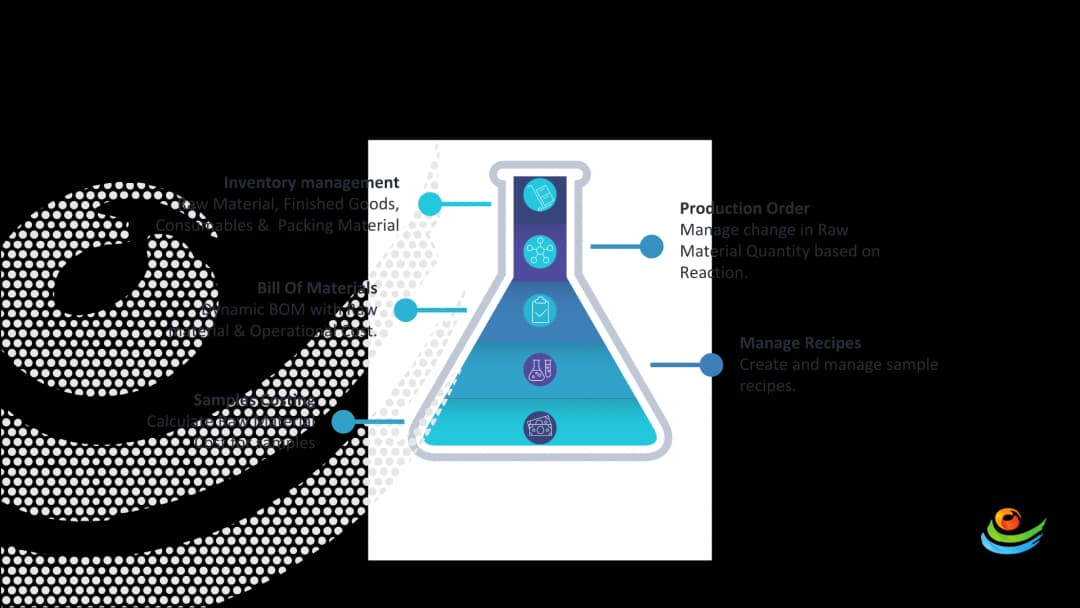

Bill Of Materials (BOM): The Bill of Materials (BOM) is a fundamental feature of the best ERP systems for manufacturing. It provides a structured list of all raw materials, components, and sub-assemblies needed to produce a finished product. By serving as a detailed production blueprint, the BOM ensures that all essential inputs are accounted for and that production costs are meticulously tracked.

Advanced Production Planning Tools: Within ERP Manufacturing, advanced production planning tools help streamline operations by creating accurate production schedules. These tools balance demand forecasts with available inventory, labour, and machine capacity. By doing so, they ensure that production processes are optimized, reducing lead times and operational inefficiencies.

Workstation Management: Workstations are crucial nodes in the production process. The best ERP systems offer intuitive tools to assign tasks, track progress, and monitor capacity across workstations. With effective workstation management, manufacturers can increase throughput, eliminate bottlenecks, and ensure that every part of the production floor runs smoothly.

Driving Operational Excellence: ERP software not only supports core manufacturing functions but actively drives business performance. By centralizing data and automating workflows, ERP Manufacturing empowers businesses to make informed decisions that enhance productivity and profitability across their entire operation.

Furthermore, the successful implementation of these strategies and tools offers several significant benefits to manufacturing companies:

Cost Control: Integrated cost tracking within ERP ensures accurate monitoring of raw material and operational expenses. This level of control is essential for staying within budget and boosting profitability.

Production Accuracy & Consistency: BOMs maintained within ERP systems standardize production processes, ensuring that every product is built to specification and minimizing costly rework.

Optimized Resource Utilization: The best ERP systems for manufacturing provide real-time visibility into labor, machine, and material usage enabling efficient allocation and minimizing idle time.

On-Time Delivery: With effective production planning and streamlined workflows, businesses can fulfill orders as scheduled, increasing customer trust and satisfaction.

Competitive Advantage: Efficient ERP Manufacturing solutions allow companies to offer superior quality, faster delivery, and competitive pricing key factors for market leadership.

Operational Agility: A robust ERP platform enables manufacturers to swiftly adapt to demand changes, supply chain disruptions, or new business opportunities.

Leveraging the full capabilities of ERP Manufacturing transforms your factory floor into a data-driven, agile operation. From production processes to cost management and delivery performance, the best ERP system for manufacturing empower your business to grow, compete, and innovate.